Plastic is a major discovery in history. It’s light, flexible yet resistant and affordable.

An invention that has changed history and everyone’s life.

This material is widely used in the homeware sector. Moreover, since technopolymers were discovered in the ‘90s, it can be used for more complex applications, such as in the medical sector, transport industry (automotive, aeronautics and aerospace), and in many other sectors, replacing heavier, more expensive and lower-performing materials.

Crea s.r.l believes that plastic will still have a major role in the future, combining innovation (which is something that has always characterised this material) with recycling, being in line with circular economy.

In terms of environmental sustainability, Crea s.r.l has always been one step ahead, as it is always looking for innovative solutions.

Thanks to our research on environmentally sustainable materials, we can provide two new materials: BIO-TECHNOPOLYMER and BIO-POLYMER+WOOD.

We will keep researching other new materials to meet the needs of each customer and provide innovative and sustainable solutions.

BIO-TECHNOPOLYMER

100% NATURAL AND BIODEGRADABLE

Crea s.r.l believes in renewable and biodegradable materials. That’s why we decided to invest in and test a new 100% NATURAL BIO-TECHNOPOLYMER, in which none of the components – base resins, colours, additives – has a chemical origin.

This material is:

This material is a compound made with different bio-technopolymers resulting from renewable sources that use biomass waste without affecting agricultural resources.

The main biopolymers results from the fermentation of some bacteria, which produce polyester through an adequately nourished bacterial culture.

This material was conceived to produce durable and semi-durable goods, but it degrades as pine or oak wood (based on tests conducted in compliance with standards ISO14855-1:2005, ISO14851 and ISO14852).

As wood, this bio-technopolymer can be used for many years but, under specific conditions, it degrades, starting a biological cycle.

This material is compostable in compliance with all international regulations (laboratory tests based on ISO 20200):

This raw material is non-toxic. Moreover, the ecotoxic effect of the compost – obtained from a disintegration process – was tested in the laboratory. Bean and barley seeds were buried in two vases filled with a mixture containing 50% of vermiculite/peat and 50% of bio-technopolymer. After 14 days, the germination capacity increased by 70% and no phytotoxic effect or signs of species variation was detected. Therefore, this material did not inhibit the plants’ growth in any way.

This material obtained 4 stars out of 4 from TUV Austria, the certification body in charge of classifying this material based on the percentage of renewable raw material content (bio-based %).

This material is particularly suitable for producing toys, office supplies, gardening accessories, brushes, houseware/crockery/vases, in the Food and Beverage sector and in many other applications.

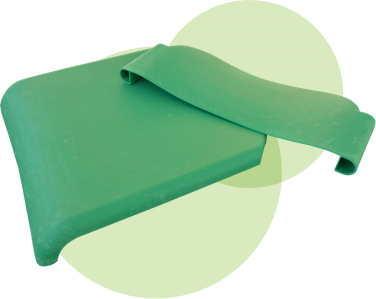

BIO-POLYMER+WOOD

ENVIRONMENTALLY-FRIENDLY

Crea s.r.l adapts to the requirements of an ever-evolving market, while having an environmentally sustainable vision. That’s why we offer a new material, which is a mixture of wood fibres and bioplastic. This material is light, flexible, durable and high-performing, as it combines the best characteristics of wood (including sustainability) and plastic.

We have tested two different types of BIO-POLYMER+WOOD, one with 35% and the other with 40% of wood fibres, each one with its characteristics.

This material is:

This material consists of BIOPOLYMERS with a wood fibre charge that ranges between 35% and 40%.

The wood fibres of this material are obtained from chips of spruce and pine trees grown in the Swedish forest in a sustainable way.

These biocomposite materials use less fossil-based materials in bioplastic items. This way, we can obtain products made with 50% of renewable materials, reducing carbon fossil up to 50%, as well as CO2 emissions and thus environmental impact during disposal.

Items made with these materials have a circular life cycle, as they can be recycled for 5 to 6 cycles.

BioPolymers containing 40% of wood fibres can come in contact with food. It has two certifications:

The two materials are similar. They both combine flexibility with resistance but have different technical characteristics.

BIO-POLYMER+ WOOD (35%)

FOOD-GRADE BIO-POLYMER + WOOD (40%)

These materials can adapt to customers’ requirements. You can enhance or mitigate the visibility of the wood fibres on the surface and increase impact resistance and/or flexibility.

These materials have the following certifications:

Bio-Polymer+Wood is the ideal alternative to different rigid plastic materials and perfect for many applications: