Nylon include all polyamide polymers. Nylon has a high water absorption power, which results in dimensional changes of the pieces, decrease in rigidity and high impact resistance.

Applications

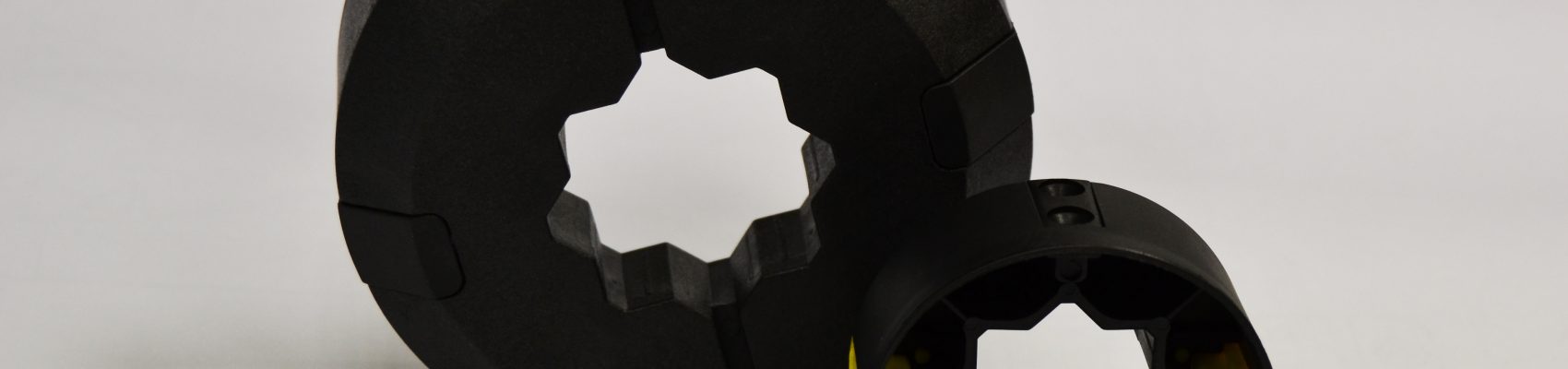

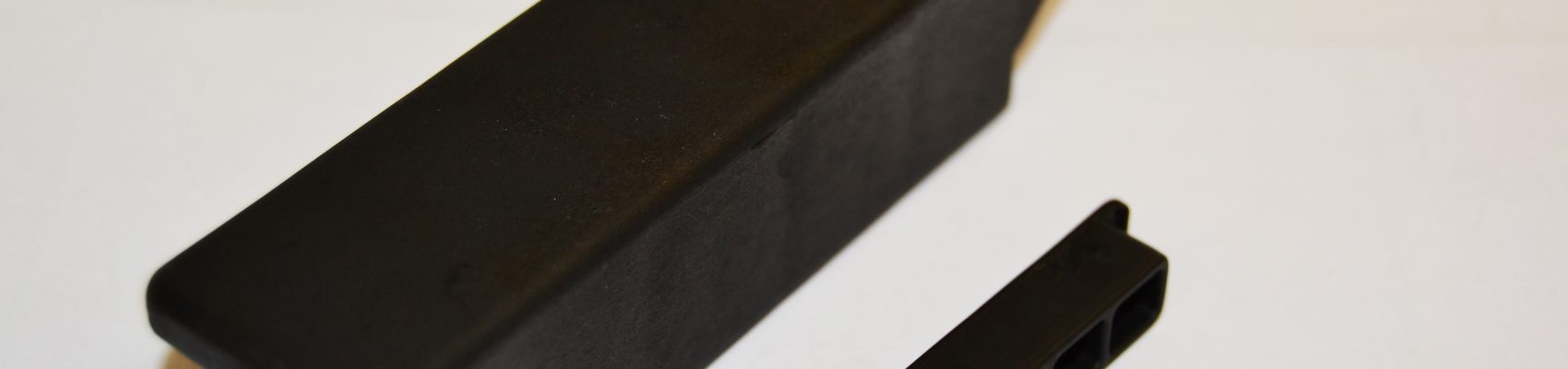

Its versatility and high physical and mechanical properties allow the moulding of these polyamides on a large scale.

Fillers

We at Crea, besides pure nylons such as PA6, PA66, and PA46, mould also compounds with the addition of:

– glass fibre: to improve dimensional stability, rigidity, and mechanical resistance and increase resistance to temperature and wear. Moreover, the presence of glass fibre limits water absorption and provides a good UV stability.

– molybdenum disulphide (MOS2): to improve rigidity, hardness and dimensional stability, resistance to abrasion and temperature. Molybdenum disulphide allows excellent sliding, wear resistant, and self-lubricating properties. This additive is often used for plastic materials that slide on metal.